|

Looking into the Workshop...

The processes from cutting a tree trunk into boards right to

the completed quality instrument requires many years of experience and

conscientiousness. To achieve concert quality the best of traditional craft

skills and technical development are brought together. Also more recent concern

for the environment did not pass unnoticed. Already in 1990 after a period of

intensive research into the woodsurface treatment of our instruments, we

changed to organic lacquers and natural oils.

We invite you to accompany

the process of making a Lyre on these two page spreads.

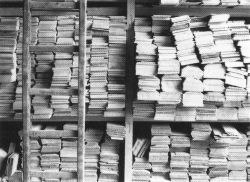

| ...Selecting wood from the

stacks. There are planks of Sycamore and Norway Spruce for framework and backs

and fronts of the instruments. Lime and poplar are used for infill and support.

To achieve the required quality of timber it must dry and be stacked and

re-stacked for about ten years prior to use. |

Norway Spruce

with cone..

Rough climatic

conditions and

the

poor soil of the

mountainous regions

ensure firm and

compact growth of

this softwood to

serve the function

of

vibration

transference which

requires elastic qualities

above

all. |

|

|

|

Sycamore in

its natural environment.

This firm deciduous

timber is responsible

for the tension

bearing stability

of the

instrument

and offers particular

qualities in the transfer

of

sound vibrations. |

... Cutting the

plank on a

bandsaw |

|

Checking the

fit

of the joit before

glueing. Glued under

pressure the frames

then need at least

four weeks to settle

in storage before

further work can be

done on them. |

|

|

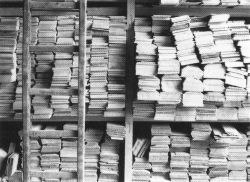

. ..A large

assortment

of side and frame pieces

is needed for selecting

different quality grades.

The wood - Sycamore

and Obeche -

must

not become too dry

in storage so that flexibility

is retained for

bending

into the required curves. |

back

|